|

|

|

|

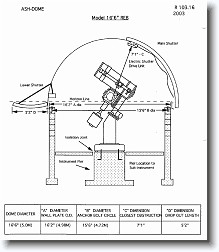

Observatory

|

|

Telescope

|

|

Pier

|

|

Mount

|

|

Camera

|

|

Miscellaneous

|

|

|

|

Specifications

|

|

Details

|

|

|

Details

|

Ash-Dome

Ash Manufacturing Company, Inc.

http://www.ashdome.com/

Box 312

Plainfield, IL 60544

USA

Telephone: 1 (815) 436-9403

Fax: 1 (815) 436-1032

- Documentation

- Assembly Instructions and Brochure (included)

- Rollers

- Dome rollers

- Heavy duty

- Self-aligning

- Grease lubricated ball-bearing type

- Galvanized

- 3 inch diameter rollers

- Roller mount

- 14 GA (.0747) Galvanized steel

- Low carbon

- Commercial quality

- Galvanized G 90 or equal

- Minimum spangle

- Extra smooth

- Oiled

- Die formed

- Conforms to ASTM specification A-569

- Roller isolation

- Roller fixtures are isolated from the wall plate assembly by 3/8 inch Isomode Pads

- 60 +/-5 Durometer Black color

- Nominal static deflection minimizing vibration through the roof structure that

could possibly be transmitted to the telescope pier

- Shutter rollers

- Heavy duty

- Self-aligning

- Grease lubricated ball-bearing type

- Galvanized

- 1 1/2 inch diameter rollers are spaced equidistant so the load of the shutter is

distributed equally around the length of the shutter section

- Bearings are rated for 5 years

- Tracks

- Dome track

- 10 GA (.1345) Galvanized steel

- Low carbon

- Commercial quality

- Galvanized G 90 Grade B or equal

- Minimum spangle

- Roll formed track

- Extra smooth surface

- Oiled

- Conforms to ASTM specification A-569

- All exterior welds are undercoated with a cold zinc primer and coated with a rust inhibitor

- Shutter track

- 12 GA (.1046) galvanized steel

- Commercial quality

- Galvanized G 90 Grade B or equal

- Minimum spangle

- Extra smooth, roll formed

- Conforms to ASTM specification A-569

- Dome

- Dome skirt

- 14 GA (.0747) Galvanized steel

- Low carbon

- Commercial quality

- Galvanized G 90 Grade B or equal

- Minimum spangle

- Extra smooth surface

- Oiled

- Conforms to ASTM specification A-569

- Roof sheets

- 26 GA (.022 - .026) Galvalume

- CHEM treated

- Oil lite

- Minimum spangle

- Segments are 16 inches wide at base (taper toward top)

- Stiffening flange roll formed on each edge (forming a weather proof structure)

- Rib sections

- Stiffening ribs

- 26 GA (.022 - .026) Galvalume

- CHEM treated

- Oil lite

- Minimum spangle

- ATSM A-792 AZ 50 coating

- Two segments are roll formed, fastened into a completed unit,

riveted every 12 inches forming an interlocking type cross-section

- Caulking compound

- Perm-E-Lastic Glazing Compound, used along view aperture framing,

forming a continuous bead of sealant. This material is supplied to fill any

seams that are to be exposed after framing has been completed.

- Weather seals

- 3/8 C.C.

- Sponge stripping, medium density, skived one side.

- Black color (contact adhesive used to secure weather seal along viewing aperture).

- All necessary clearances are sealed with a sponge type neoprene weather seal. This effectively

keeps out severe amounts of rain, dust and snow.

- Motors

- Shutter motor

- 1-speed inline gear motor with reversing capability

- 1/4 HP, 115 V, 60 cyc, 1 ph

- CSA certified 42492

- Limit switch provided so as to shut off motor when shutter travel reaches

extreme open or close position.

- Motor and gear reduction equipment furnished on a mount that allows for

continuous proper alignment throughout travel of the shutter section.

- All main shutter sections are driven with electric motor rack and gear

device, unless otherwise specified.

- Disconnect motor lead to switch furnished.

- Azimuth drive

- 1-speed capacitor start, end mounted motor with reversing capability

- 1/4 HP, 115 V, 60 cyc, 1 ph

- NEMA 56 C face

- Motor is mounted to a C face right angle speed reducer 60:1 reduction (standard)

- This is a positive rack and gear system electrically operated, unless otherwise

specified.

- Furnished motor and gear reduction mount suitable for adjustment and alignment.

Notes

- Galvalume

- A corrosion resistant sheet

- Continuously hot-dipped coated with an aluminum zinc alloy

- Conforms to ATSM A-792 A-792 AZ 50 coating

- Roof panels and Rib sections are secured on the outside of the dome skirt.

This action prevents water from entering the Dome Roof Structure as all

interlocking joints are on the outside of the dome skirt.

- Typically, all fasteners on the dome are 18-8 series - stainless steel;

satisfies all requirements of ASA B 182 - 1960 MS 35308

|

|

|

|

|

|

|

|

|

|

|